Product Introduction

Suitable for solar panel making machine in solar panel factories

1. Production module type: single-glass, double-glass module.

2. Module cell size: 166-210mm.

3. Module size: L(1650~2500mm) x W(990~1400mm) x T(25~45mm).

4. Module welding tape type: flat welding tape/round welding wire;

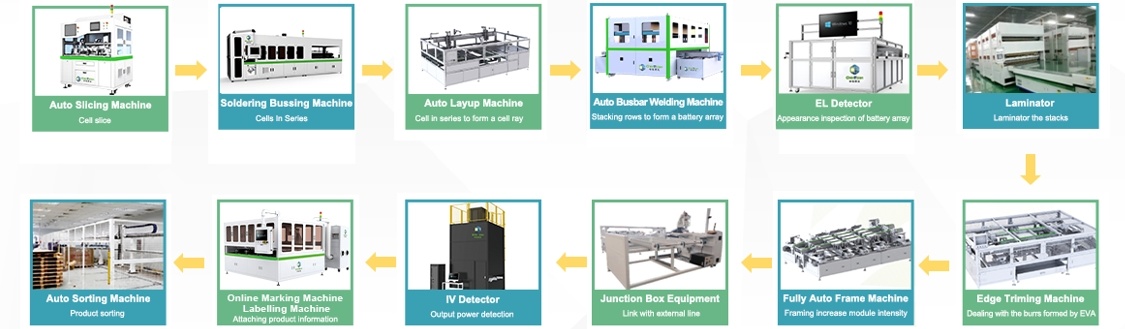

PV module production and manufacturing process

Key Attributes

| No. | Process flow | Equipment | Qty |

| 1 | Stringing and Bussing | Auto glass loading machine | 1 |

| 2 | 1st EVA Cutting and Laying Machine | 1 |

| 3 | 7200 High-speed Scribing&Stringer Integrated Machine | 3 |

| 4 | Robot Layup Machine | 3 |

| 5 | Auto Bussing Machine | 1 |

| 6 | Auto Taping Machine | 1 |

| 7 | 2nd EVA Cutting&Laying Machine | 1 |

| 8 | TPT Cutting and Laying Machine | 1 |

| 9 | 2nd Glass Loading Machine | 1 |

| 10 | Testing Before Lamination | EL+VI Tester | 2 |

| 11 | Double-glass Repair Transplanting Machine | 2 |

| 12 | Double-glass Side Sealing Machine | 2 |

| 13 | Laminator Material In and Out | Double-layer Double-chamber Laminator | 2 |

| 14 | Assembling and Testing after Lamination | Auto Edge Trimming Machine | 2 |

| 15 | 3-in-1 Auto Framing Machine | 1 |

| 16 | Auto J-Box Glue Dispenser Machine(offline) | 1 |

| 17 | junction box weldingmachine | 1 |

| 18 | Auto J-Box Installation machine | 1 |

| 19 | Auto J-Box Glue Filling Machine | 1 |

| 20 | Curing Line | Curing Line | 1 |

| 21 | Final Check | Auto Corner Filling Machine | 1 |

| 22 | Auto Labeling Machine | 1 |

| 23 | IV Tester | 1 |

| 24 | HIPOT | 2 |

| 25 | EL Tester | 1 |

| 26 | Final Check | 2 |

| 27 | Auto Corner Wrapping Machine | 1 |

| 28 | Auto Grading Machine | 1 |

Packaging and delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.