Solar cell cutting technologyIssuing time:2024-03-14 15:04 As the core component of solar power generation systems, the cutting technology of solar cells directly affects the efficiency and cost of the solar energy industry. The cutting of solar cells refers to the process of cutting silicon chips into small pieces of specific shapes and sizes for assembly into solar panels. The cut solar cells need to have efficient photoelectric conversion performance and stable electrical characteristics to ensure the performance and reliability of the entire solar energy system.

At present, the cutting of solar cells mainly adopts two main methods: mechanical cutting and laser cutting. Mechanical cutting is one of the most traditional methods, which uses mechanical equipment such as drilling and saw blades to cut silicon chips. This method has lower cost, but relatively lower accuracy, which can easily cause chip damage and waste. Laser cutting is a high-precision, non-contact cutting method that can achieve precise cutting of silicon chips, reduce chip damage, and improve cutting efficiency. In addition to the selection of cutting methods, the cutting of solar cells also needs to consider the control of parameters such as cutting angle, cutting speed, and cutting depth. A reasonable cutting angle can reduce chip damage and energy consumption during cutting, improve cutting efficiency and chip utilization. Meanwhile, the control of cutting speed and depth can also affect cutting quality and cost, and needs to be adjusted according to specific process and equipment characteristics.

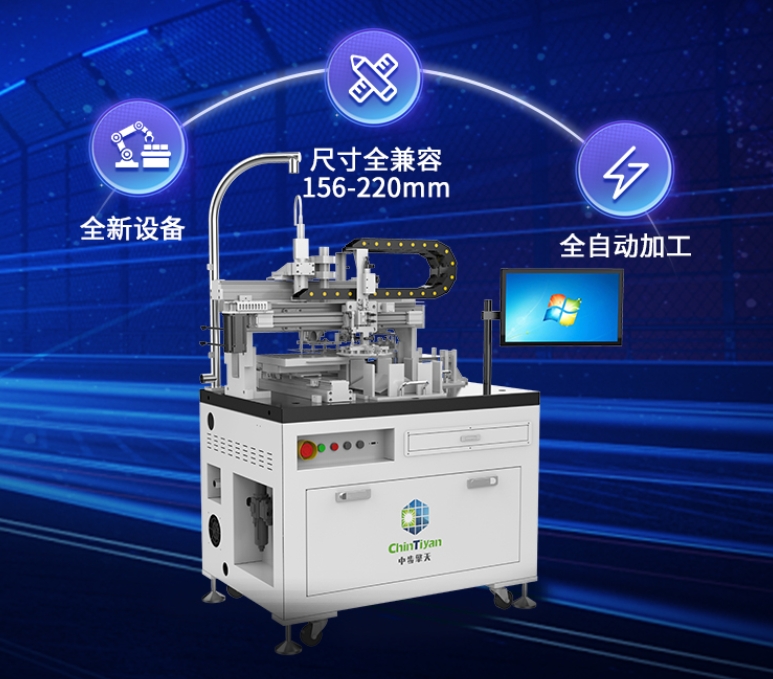

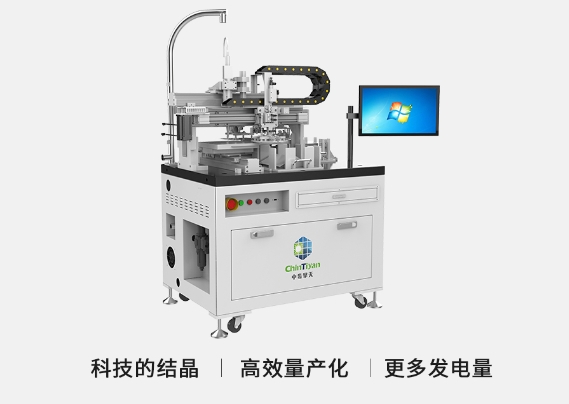

With the rapid development and technological progress of the solar energy industry, the cutting technology of solar cells is constantly innovating and improving. In the future, with the continuous increase in the size of solar cells and the application of thin film technology, cutting technology will face more challenges and opportunities. Firstly, as the size of solar cells increases, the requirements for cutting accuracy and efficiency will also become increasingly high. Traditional mechanical cutting methods may not be able to meet the needs of large-sized battery cells, while laser cutting technology can better address this challenge and achieve efficient cutting and processing of large-sized battery cells. Secondly, the rise of thin-film solar cells has also provided new challenges for the development of cutting technology. Compared to traditional silicon chips, thin-film batteries have the characteristics of being thinner, lighter, and more flexible, which puts higher demands on cutting processes and equipment. Therefore, future cutting technologies may place greater emphasis on adaptability and precise processing capabilities for thin-film batteries. In addition, with the development of artificial intelligence and robotics technology, the cutting process of solar cells will also move towards automation and intelligence. Intelligent cutting equipment can achieve real-time monitoring and adjustment of cutting parameters, improve cutting quality and efficiency, reduce labor costs and production cycles. Zhongbu Qingtian New Energy (Hubei) Co., Ltd. produces solar cell laser cutting machines, injecting new vitality into the sustainable development of the solar energy industry In summary, the cutting technology of solar cells is an indispensable and important link in the development of the solar energy industry. With the continuous innovation and progress of technology, it is believed that the cutting technology of solar cells will play an increasingly important role in the future, opening up broader prospects for the development of the solar energy industry. 聲明:此篇為中步擎天原創,轉載請標明出處鏈接:http://www.npcnn.cn/en/sys-nd/43.html

|