The development of crystalline silicon battery technology presents diversification, and N-type battery enterprises are rapidly expanding productionIssuing time:2024-04-12 14:53 The improvement of photovoltaic conversion efficiency brought about by the technological transformation of battery cell preparation is one of the important paths to reduce the cost of photovoltaic power generation. Under the same lighting conditions, the higher the photoelectric conversion efficiency of the battery, the more electricity it generates, and the lower the unit cost of photovoltaic power generation, which is more conducive to the promotion and application of solar power generation systems.

Therefore, improving the photoelectric conversion efficiency is a key direction for technological research and development in the battery cell industry. The emitter and back passivation (PERC) cell technology has the advantages of high conversion efficiency, relatively simple process, mature equipment and technology, and has become the mainstream high-efficiency technology route. However, in 2023, the average conversion efficiency of single-crystal PERC cells in mass production will reach 23.4%, which is close to the production efficiency limit of 24.5%. Other high-efficiency battery technologies include tunneling oxide passivation contact (TOPCon) battery technology, interdigital back contact (IBC) battery technology, heterojunction (HJT) battery technology, and other N-type high-efficiency battery technologies, which have greater potential for efficiency improvement and are expected to achieve a mass production conversion efficiency of 28%. After continuous verification in recent years, many efficient battery technologies have gradually entered the import period of large-scale production since 2021. Existing manufacturers and new entrants in the battery industry are actively laying out efficient battery production capacity. According to data from the China Photovoltaic Industry Association, the proportion of N-type batteries has significantly increased from 9.1% in 2022 to 26.5% in 2023. According to Dongwu Securities' "2024 Photovoltaic Strategy Report: Accelerating Capacity Release to Bottom, Embracing a New Era of Light Storage Parity", the production capacity of TOPCon cells, HJT cells, and BC cells at the end of 2023 is approximately 475GW, 62GW, and 58GW, respectively. It is expected that by the end of 2024, the production capacity will reach 798GW, 84GW, and 104GW, respectively, which means that the long-term demand for N-type high-efficiency silicon wafers will be close to 1000GW. Therefore, the development and application of efficient battery technology will effectively drive the demand for upstream efficient silicon wafers.

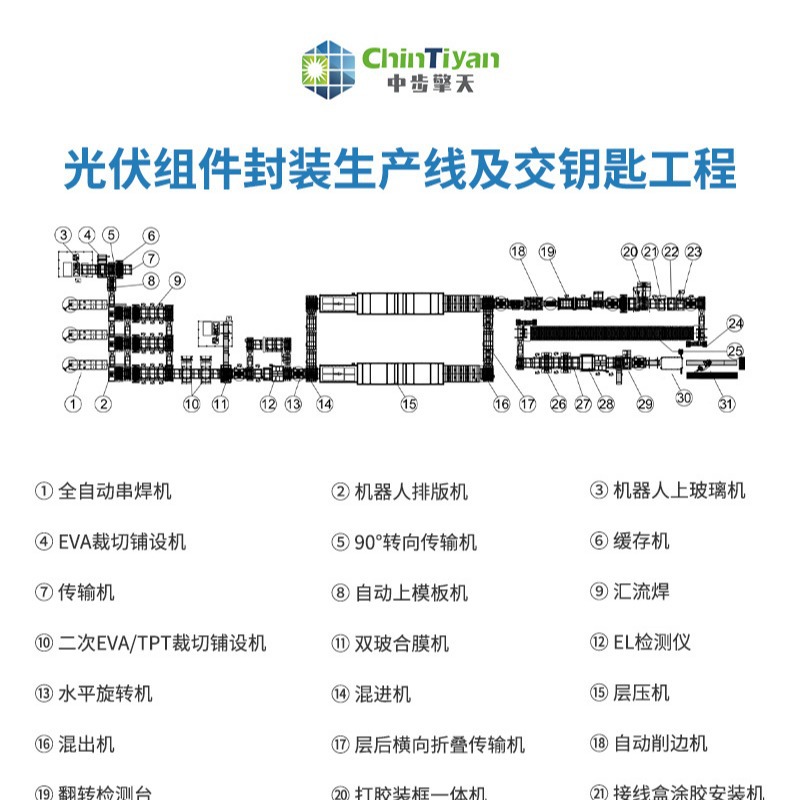

Zhongbu Qingtian New Energy provides a 10-500MW photovoltaic module automation production line solution, providing project planning, whole line equipment, process technology and other support. We can customize various levels of automation and semi automation production lines for customers based on their different needs, including factory layout, equipment configuration, and production line planning. 聲明:此篇為中步擎天原創,轉載請標明出處鏈接:http://www.npcnn.cn/en/sys-nd/40.html

|