Photovoltaic technology route: sorting out the BC battery industry chainIssuing time:2024-04-22 14:22

From a structural perspective, photovoltaic modules can be divided into single glass and double glass, with the main difference being the materials used on the back. The back of the single glass uses a backing plate, while the back of the double glass uses glass, as shown in the following figure: The BC cell industry chain in the photovoltaic technology roadmap is a complex and multi link system. The following is a detailed overview of the BC battery industry chain:

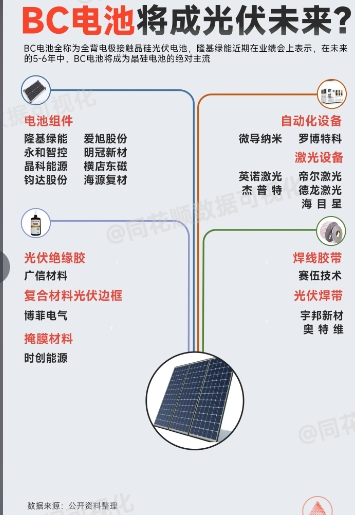

1. What is BC battery? BC cells are efficient photovoltaic cells, also known as back contact cells. The technical feature of BC cells is to move the PN junction and metal contact of solar cells to the back of the cell, so that there will be no metal electrode blocking the front of the cell, thereby maximizing the use of sunlight, reducing optical losses, increasing effective power generation area, and improving conversion efficiency. The front of BC batteries is usually covered with a SiNx/SiOx double-layer anti reflection passivation film to further enhance performance. This battery technology is suitable for various photovoltaic products due to its high efficiency, low attenuation, and good temperature coefficient, and has broad application prospects and market potential. The theoretical conversion efficiency limit of BC is 29.1%, which is higher than the 28.7% and 28.5% of TOPCon and HJT. At present, the main companies that have achieved mass production of BC batteries are Longi, Aixu, and Maxeon (with TCL Zhonghuan holding shares). Longi uses HPBC technology, Aixu uses ABC technology, and Maxeon uses IBC technology. 2. Advantages and disadvantages of BC batteries Advantages: BC batteries can be organically combined with TOPCon, HJT, perovskite and other technologies, incorporating other technological advantages and further improving conversion efficiency. Compared to TOPCon and HJT batteries, BC batteries have the highest theoretical conversion efficiency. While achieving high conversion efficiency, XBC batteries also take into account high aesthetics. Disadvantages: The equipment cost of BC batteries is relatively high, mainly due to their complex structure and manufacturing process. BC technology is more difficult than HJT and TOPCon technologies, and large-scale industrialization is still challenging at present. 3. BC Battery Industry Chain Like other photovoltaic cell industry chains, BC cells can be divided into upstream, midstream, downstream, equipment, and auxiliary materials. Upstream: silicon materials, silicon wafers Silicon materials: Tongwei Corporation, Daquan Energy Silicon wafers: TCL Zhonghuan, LONGi Green Energy Midstream: battery cells, components Battery cells: Longi Green Energy, Aixu Co., Ltd., Yonghe Intelligent Control, Jingke Energy Downstream: Photovoltaic power station Photovoltaic equipment: Di'er Laser, Inno Laser, Delong Laser, Golden Orange, Robotec, Micro Nano, Haimu Star, Jept, Zhongbu Qingtian Auxiliary materials: silver paste, welding tape, POE adhesive film, coating, etc Photovoltaic silver paste: Juhe Materials, Dike Co., Ltd., Suzhou Gude Photovoltaic ribbon: Ubon New Materials POE film: Yuxing Corporation, Haiyou New Materials Photovoltaic coating: Guangxin Materials Photovoltaic frame: Bofei Electric POE film: Yuxing Corporation, Haiyou New Materials Mask material: Shichuang Energy 4. Current BC Future At present, TOPCon batteries are still in the mainstream position in the industry, with a significant expansion in production capacity, and the main problem is the potential for overcapacity. Jingke Energy's view: We firmly believe that TOPCon is the mainstream technology, but we also have reserves for BC batteries. JinkoSolar: Firstly, we firmly believe that TOPCon will be the mainstream technology in the next 3-5 years. However, the company also has relevant technical reserves for BC. In our opinion, BC batteries are relatively more aesthetically pleasing and may have their own market space in distributed and other aspects. 5. Industry Logic 1) Aixu Corporation and Longi Green Energy have already started production of BC batteries, which are currently the leaders in BC batteries. 2) Compared to upstream silicon materials and wafers, photovoltaic equipment and auxiliary materials are more valuable, and BC cells have a higher demand for laser equipment. 3) At present, BC batteries are still in their infancy, and the mainstream is still TOPCon batteries. 4) The overall background of photovoltaics is to improve efficiency and reduce costs. BC cells need to wait for relevant companies to put them into mass production to see if they can really improve efficiency and reduce costs. 5) The advantages of BC technology are prominent, but its technical barriers and equipment costs are currently the challenges Within the next year, you can follow the information of Zhongbu Qingtian New Energy and stay up-to-date with the latest developments related to BC components. Zhongbu Qingtian New Energy is a high-tech enterprise specializing in the research and development of photovoltaic module automation production line equipment. Through long-term market research and customer feedback, the company has developed six advanced and highly compatible equipment, including BC high-speed serial welding machine, BC low-speed serial welding machine, BC high-speed non-destructive cutting machine, BC low-speed non-destructive cutting machine, cutting and welding integrated machine, and laser frame marking machine, to meet the diverse needs of the market. The product is independently developed and designed, providing customers with one-on-one differentiated customization to help enterprises achieve production capacity improvement. 聲明:此篇為中步擎天原創,轉載請標明出處鏈接:http://www.npcnn.cn/en/sys-nd/38.html

|