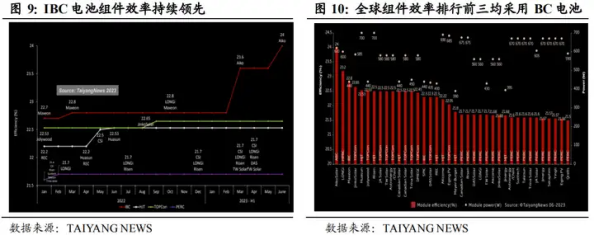

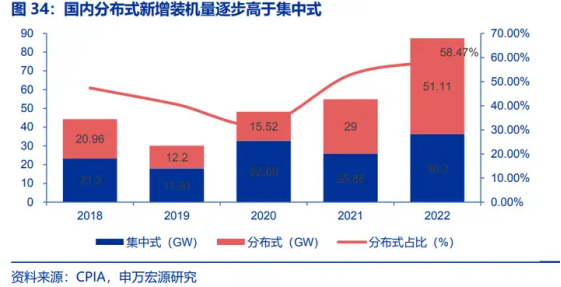

BC knowledge quiz! [Suggested Collection]Issuing time:2024-08-20 16:21 BC cell, also known as "full back electrode contact crystalline silicon photovoltaic cell", is an innovative solar cell technology. Its uniqueness lies in the electrode design located on the back of the battery, which fully exposes the front to sunlight, thereby enhancing the absorption efficiency of light. This design also shortens the current transmission path, reduces resistance, and thus improves battery performance. With the simplification of BC battery process flow and breakthroughs in key manufacturing technologies, its mass production process is expected to accelerate. Especially when combined with other battery technologies, XBC cells have signi ficant advantages in efficiency and appearance, indicating that BC cells may become one of the next generation mainstream photovoltaic cell technologies. The advantages of BC components are mainly reflected in the following aspects: High battery efficiency: There is no metal grid line blocking the front, eliminating the loss of shading current and maximizing the utilization of incident photons. The short-circuit current is increased by about 7% compared to conventional batteries. The front side has no electrode contact effect, optimizing the suede structure and passivation anti reflection layer, improving light absorption and reducing carrier recombination loss, thereby improving open circuit voltage and short-circuit current, and achieving higher conversion efficiency. Highly optimizable gate line design: Both positive and negative metal electrodes are located on the back of the battery, without considering the problem of gate line obstruction. The metal gate line structure can be maximally optimized, such as increasing the gate line width and optimizing the gate line shape, to reduce the series resistance of the battery and enhance the back reflection function of long wave photons, improve the battery fill factor and short-circuit current. Convenient packaging process: Back contact batteries facilitate component packaging and can be connected in a coplanar manner through automated operations, eliminating the need for traditional battery soldering and reducing the adverse effects of pressure deformation. Beautiful appearance: The back contact battery module packaging can reduce battery gaps, increase battery density per unit area, and increase power generation. At the same time, its front color tone is more uniform and beautiful, suitable for photovoltaic building integration (BIPV), and has good commercial prospects. In terms of market space, BC batteries demonstrate broad application potential: Wide application scenarios: BC cells are naturally suitable for distributed photovoltaic scenarios, especially BIPV, due to their beautiful appearance and good integration with architectural art. Taking Europe as an example, its new installed capacity is mainly distributed, and it prefers a black roof building style that is in line with the characteristics of BC batteries. In recent years, the growth rate of distributed installed capacity at home and abroad has been significantly higher than that of centralized installed capacity. In 2022, the proportion of newly added distributed installed capacity in China reached 58.47%.

The increase in market share of centralized power stations: BC batteries are less commonly used in centralized power stations, mainly due to their low double-sided rate and high cost. However, technological advancements are expected to increase the full lifecycle power generation of BC batteries, and as costs gradually decrease, their market share in centralized power stations will gradually increase.

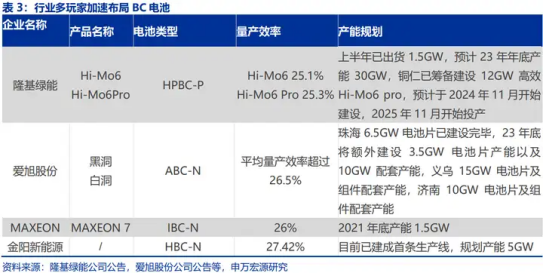

The industrialization layout of leading enterprises: Leading enterprises in the photovoltaic industry have a significant impact on the direction of new technology development. The industrialization of new technologies faces challenges of complex processes and high costs, which require the leadership of top tier manufacturers to solve. Taking TOPCon batteries as an example, the layout of top tier manufacturers such as JinkoSolar has accelerated their industrialization process. Leading companies such as Longi Green Energy have publicly expressed their optimism towards BC batteries, attracting a lot of attention and driving more companies to invest in the research and manufacturing of BC batteries.

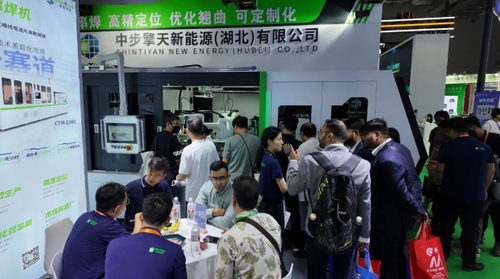

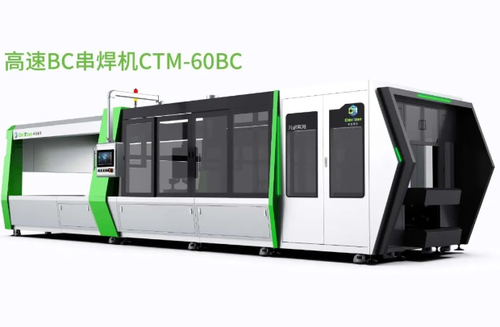

Accelerated expansion of BC production capacity: LONGi Green Energy has basically overcome the process difficulties of PN junction isolation and battery series connection. Existing and pending projects are planned to be completed and put into operation gradually from 2024 to 2026, and it is highly likely that BC technology will be the main focus. Aixu Corporation has also planned to expand the production capacity of ABC battery modules. With the accelerated expansion of BC battery module production capacity, related equipment suppliers are expected to benefit, especially the increasing demand for high-precision string welding machines. Leading manufacturer of massproduced series welding equipment without grid lines on the front As a leading supplier of integrated solutions for photovoltaic module automatic production lines, Zhongbu Qingtian focuses on the deep cultivation of welding technology and automated manufacturing, constantly exploring the core technologies of module manufacturing. At this year's SNEC exhibition, the company attracted high attention and praise from global exhibitors and industry experts with its self-developed fully automatic high-speed BC string welding machine CTM-60BC.

This device adopts a unique process, effectively solving the problem of mass production of BC battery components, achieving a production capacity of 6000 pieces/hour, and helping customers improve the efficiency of component mass production to over 20%. Its overall functional structure is compact, occupying only 30 square meters, achieving higher production capacity with a smaller volume.

This device adopts infrared lamp welding and other technologies to achieve precise temperature control, greatly reducing the degree of warping of battery cells and effectively ensuring the high quality and reliability of components. In terms of compatibility performance, Zhongbu Qingtian's fully automatic high-speed BC string welding system has demonstrated excellent adaptability, which can be customized to be compatible with various high-capacity batteries such as polycrystalline, monocrystalline PERC, TOPCon, heterojunction, and SMBB. Even when facing materials with high welding difficulty, it can generate the optimal temperature control curve, significantly improving string yield and welding efficiency.

In addition, the device also integrates an AI numerical control system based on artificial intelligence technology, which realizes functions such as fully automatic visual inspection, online monitoring, intelligent diagnosis, and fault warning, helping customers reduce costs and increase efficiency, completing the intelligent transformation of photovoltaic production, and playing an important role in energy conservation, consumption reduction, and refined management.

Zhongbu Qingtian New Energy Company relies on strong technical support and talent support from academic institutions such as Wuhan University and Hubei University of Technology, and has gathered a senior R&D team of over 60 people to fully build a strategic technology innovation platform. The company has independently developed and designed multiple equipment, including fully automatic high-speed BC string welding machines, low-speed BC string welding machines, fully automatic double track string welding machines, high-speed laser cutting machines, typesetting and convergence welding machines, conventional laser cutting machines, online frame marking machines, etc., to help promote the speed of production of photovoltaic modules and contribute intelligent manufacturing strength to the production of photovoltaic cells and the development of green energy in China and even the world.

聲明:此篇為中步擎天原創,轉載請標明出處鏈接:http://www.npcnn.cn/en/sys-nd/229.html

|